S120IP

Ascott salt spray test chambers

– one of the world’s most modern and most versatile salt spray corrosion test systems – and with design, ergonomics and quality that’s in a class of its own.

Chambers to cover every testing requirement from continuous salt spray test through to condensation humidity and modified tests.

Two specification levels:

Standard (iS)

Standard models meet the requirements of basic, continuous salt spray tests conducted at a single temperature only, such as ASTM B117, ISO 9227, JIS Z 2371 and similar international test standards, and may be used with pH neutral salt solutions (NSS) or those acidified by the addition of Acetic Acid (ASS) or Cupric Acid (CASS).

Premium (iP)

Premium models can perform the same basic salt spray tests, but in addition are equipped with extra features which enable them to undertake ‘modified’ tests such as those defined in ASTM G85. Here conventional salt spray is often combined with one other climate, in a two-part cycle, to accelerate the test. For example: salt spray and condensation humidity (SWAAT) or salt spray and drying (PROHESION) or salt spray and SO2 testing. (ASTM G85 A4)

FEATURES

All Ascott corrosion test chamber models feature:

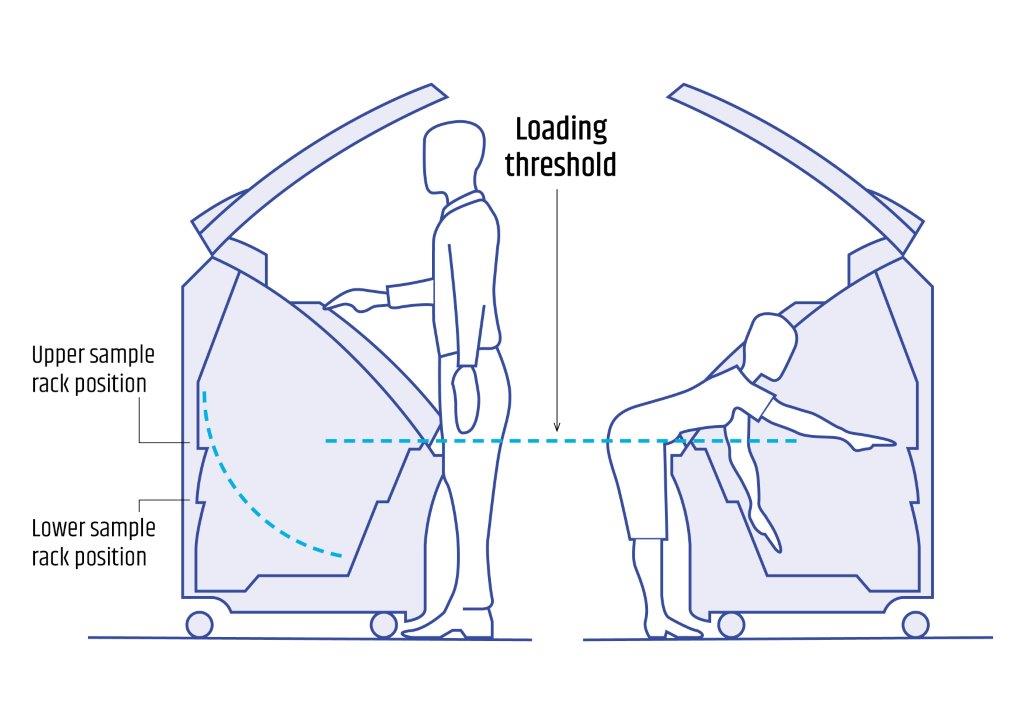

- Low loading threshold for ergonomic loading and unloading.

- ‘Easy Open’ pneumatically operated canopy, with safety interlock.

- Dry seal gasket to prevent wetting the operator’s clothes.

- Timed canopy lock and automatic purge of the cabinet interior with fresh air after testing and before the chamber is opened.

- Easily accessible salt spray atomizer(s) in transparent hard-wearing acrylic, for ease of maintenance.

- External portable salt solution tank for ease of cleaning. 115L for 300/400L, 73L for 450L, Chambers and 90L for 1000L Chambers and above.

- Central viewing window for unimpeded visual access to chamber interior and test material.

- Base castors and integrated fork lift lift truck runners, for ease of transportation.

- A free choice of canopy colour.

- Calibration certificate.

- Consumables spares kit.

- Fallout Measuring Kit

Additional features of Premium Salt Spray Chambers:

- Integrated immersion heater to create condensation humidity, for testing to a wider range of ‘modified’ salt spray tests.

- Intuitive 7” touch-screen, full colour user control interface, employing the latest version of our highly intuitive operating software, for ease of programming and use.

- The operating software has a very large capacity for the creation of complex multi-step test programmes, so that the widest possible range of test profiles can be accommodated.

- The icon based control interface offers a variety of languages built-in for ease of understanding and use.

- RJ45 communications port enabling the chamber to be wired or wirelessly connected to a local area network (LAN) for logging and remote programming via a computer running optional software.

- A real-time, user configurable ‘clock’ to enable different test samples to be batched and have their exposure time monitored separately, with alarms to warn when a pre-set test period has been completed.

- On/Off function with Temperature control for intermittent salt spray applications.

- Ambient drying function to open/close the canopy during a test, exposing the samples to ambient conditions in the room.

PRODUCT SPECIFICATIONS

Specifications

Standard salt spray chambers

S120iS

Premium salt spray chambers

S120iP

Chamber Capacity

120 Ltrs/

4.2cu ft

Mounting Format

Bench top

Loading threshold

280mm/11″

Chamber external dims, max

W : 1315mm/51.8″

D : 680mm/26.8″

H : 800mm/31.5″

Chamber internal dims, max

W : 715mm/28.2″

D : 490mm/19.3″

H : 490mm/19.3″

Salt solution reservoir ext. dims.

N/A

Chamber construction

Glass reinforced plastic, Polypropylene & ABS parts

Color

9 Standard Colours to choose from

Electricity supply | Standard models | Premium models

1 phase

Voltage (VAC) and frequency (Hz) dependent on country/region of installation

Water Requirements

Deionized/distilled for topping up air saturator and making salt solution. Air saturator requires a continuous water connection 2.5-5.0 bar (36-73 psi). If air saturator is topped up manually option ACC66 must be ordered.

Air Requirements

Clean dry & oil free, 4.0 to 6.0 bar (58-87psi) with 240 Ltrs (8.5cu.ft) per minute flow

Exhaust Requirements

3m (10ft) exhaust pipe is provided which should be terminated outside building (See Accessory ACC58)

Drain Requirements

3m (10ft) drain pipe provided which should be terminated into floor level drain (See Accessory ACC58)

Operating environment conditions

+18 to +23°C (+64 to 73°F), 85% max RH (non condensing) ambient