COF TESTER

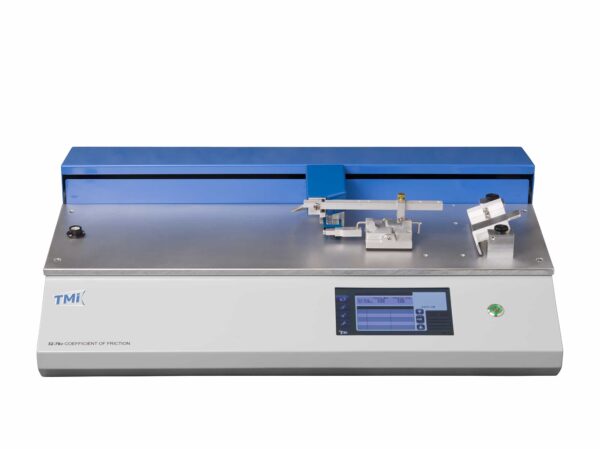

Testing Machines Inc. Coefficient Friction/Peel Tester 32-76e

Our 32-76e coefficient of friction tester offers unparalleled performance and flexibility to test across a wide range of standards for COF, peel testing, adhesion testing and heat seal applications.

Developed by Testing Machines Inc, our paper and flexible packaging testing brand, this horizontal bed coefficient of friction tester is the ultimate static and dynamic testing machine for a wide range of paper, corrugated, flexible films, rigid plastics and engineered surfaces.

The 32-76e coefficient of friction and peel tester uses advanced digital force signaling and high-speed data acquisition software to provide unmatched precision and repeatability. If you need to know how to measure coefficient of friction successfully, this is the device for you!

An easy-to-use coefficient of friction tester

Our coefficient of friction tester includes a color touchscreen display and an intuitive software user interface for easy navigation and test method storage.

Comes with seal strength and peel strength software

Our coefficient of friction tester comes with a comprehensive peel strength and heat seal application. Use it to enter a variety of peel strength parameters designed to support most international peel test and heat seal international standards. Choose from the selectable units, and both pre-peel and peel distance settings, for flexible test method set-up and storage.

Seriously a-peeling coefficient of friction testing

Our coefficient of friction tester features a T-Peel fixture that’s

designed to measure the adhesive force of a heat seal or

adhesive bonded substrate.

Our coefficient of friction tester covers all angles!

Our 180-degree peel fixture measures the release strength

of a label, or the peeling strength of an adhesive substrate. It includes a set of two test clamps that enable you to accurately inspect the release strength of labels and tapes.

The hottest in coefficient of friction testing!

During the manufacture and converting process of plastic films, the material is subjected to elevated temperatures.

When using a heated platen, it’s common for the heated surface for many plastic films to produce an increase in coefficient of friction. To measure this behavior, our coefficient of friction tester is available with an optional heated platen that can be set at temperatures from ambient to 162° C (325°F), meeting ASTM D1894 standards for heated friction testing.

Coefficient of friction test data

Our GraphMasterPro™ software is a Windows™ based software data collection program capable of providing test curve analysis, result data, data storage, exporting and printed reports.

This coefficient of friction tester software automatically captures

individual test results and raw data. In addition to collecting data from instruments manufactured by Testing Machines Inc. or Messmer Büchel, GraphMasterPro™ can be configured to communicate with instruments manufactured by other suppliers too.

Coefficient of friction applications

Whether you work with plastic films, packaging, paper, labels, coatings, cartons, adhesives, foils or printed materials, you’ll achieve the results you need with our coefficient of friction tester.

Coefficient of friction testing to international standards

Our coefficient of friction tester will help you to carry out tests like the peel test or the adhesion test to the most stringent of international standards, including:

- ASTM D 1894

- ASTM D 3330

- ASTM F 88

- FINAT1

- ISO 8295

- PSTC 101

- TAPPI T 549.

Coefficient of friction testing portfolio. In the Industrial Physics portfolio we have lots of different devices that are designed for all types of friction testing applications.

Also from TMI, our Slide Angle Coefficient of Friction (COF) Tester 32-25 provides a static COF measurement via the inclined plane method, conforming to several international standards.

Or why not check out the Slide-Angle COF Sled, designed for TAPPI T 815 testing of packaging materials and fiberboard?

Our testing knowledge is hard to beat!

We’ve learnt a thing or two about best practice when it comes to coefficient of friction testing to international standards. We like to share this insight with our customers through the knowledgebase of this website.

Here you’ll find some of the blogs we have published, like this one – our guide to coefficient of friction testing. Or maybe you’d prefer to read some technical tips for coefficient of friction testing?

FEATURES

- 7″ full-color digital touchscreen display

- High speed data collection and analysis for precise measurement of static COF with 500 readings during the first second

- Selection of test type-COF/Friction, T-Peel and 180° peel

- Heated platen option, ambient to 162° C (325° F)

- Selectable units (COF, g, N, kg, lbs, and ounce)

- Selectable load cells from 5 to 100 N

Automatically reports static and kinetic friction results after measurement - Settable distance and time for static, kinetic and peel strength

- Peel test results include average, minimum, maximum and SD of peel force

- Test storage including individual results up to 100 readings, average and standard deviation

- Direct drive arm with unique skid control.

- Sled-connecting mechanism ensures level pulling action

- New magnetic sled simplifies testing and throughput

- Direct output to PC-based GraphMasterProTM software providing coefficinet of friction/ peel test curve analysis, storage and reports

- Mini USB output for PC connection (GraphMasterPro compatible)

USB output for data storage.

PRODUCT SPECIFICATIONS

SKU: 32-76-00-0002

Applications: Adhesion Testing, Coating Testing, Coefficient of Friction Testing, Corrugated Testing, Materials Testing

Materials: Adhesive, Film, Foil, Paper, Plastics and Polymers, Textile

Model: 32-76-00-0002

Load cells: 5N, 10N, 20N, 50N, and 100N

Speed range: 10-50 cm/min (4-20 in/per min)

Travel Distance: 2.5 to 30.5 cm (1 to 12 in)

Accuracy: +/- 0.1 % of load cell capacity

Resolution: resolution will change depending on load cell in use)

Available sleds: 100 g – 1816 g (System software accepts variable sled weights) Please specify sled.

Weight: 25 kg (55 lb)

Instrument size WxDxH: 515mm x 495mm x 508mm (20.3in x 19.5in x 20in)

Power input: 120/240 VAC 50/60 Hz

Data output: USB flash drive, USB ESC/POS printer, mini USB, GraphMasterPro.

Complies with: ASTM D 1894, ASTM D 3330, ASTM F 88, FINAT1, ISO 8295, PSTC 101, TAPPI T 549.